5 of the Most Advanced Construction Materials on the Market Today

Like most areas of technology, the development of construction materials has come a long way in just a few short years. The cutting-edge products available now are safer, stronger, more efficient and more eco-friendly than their predecessors.

Here are five of today’s most exciting innovations in construction materials:

1. Super Insulating Materials

Energy efficiency is increasingly important in today’s construction environment. So, the choice of good building insulation is a top priority. In that regard, new super insulating materials (SIM) offer great promise. Fiberglass remains the most commonly used insulation material, as it combines acceptable insulating properties with low relative cost and fire-resistant qualities.

But these SIMs take insulation efficiency to a new level:

Vacuum insulated panels (VIP) consist of a metallized polymer laminate envelope surrounding a core of porous material from which air has been evacuated. The resulting product is several times more efficient than conventional insulation. Even a very thin VIP can provide excellent insulating properties, making it ideal for uses where space is limited.

VIPs are still relatively expensive to produce, so they are used most often for smaller items that require maximum efficiency—such as refrigerators, freezers, and insulated shipping containers. They cannot be cut to fit, since that would destroy the vacuum that provides their insulating properties. The same result occurs if they are punctured or torn in the process of installation. For these reasons, their use in building construction has been limited. But that’s changing. Builders in Europe are already finding it advantageous to use VIPs for general construction. And American builders are not far behind.

Gas-filled panels (GFP) employ a similar approach. But, instead of a vacuum, the panel interiors are filled with a gas such as argon or krypton. Thus far, GFPs are mainly used mainly for freezing and refrigeration applications. But their adaptability for building has been noted—especially for manufactured units that involve preset dimensions.

These super insulating materials are bound to find wide construction applications in the future because of their light weight, compact dimensions, and extraordinary insulating properties.

2. Magnesium Oxide Board

Magnesium oxide (MgO) has found a wide range of uses in today’s construction industry. Being exceptionally resistant to mold, moisture, insects, bacteria, water and flame, MgO boards have begun to replace gypsum sheetrock as the preferred material for wall panels. MgO is also remarkably strong, making it useful even for flooring and external siding. That strength allows builders to use MgO boards as thin as 10 mm for wall panels.

MgO (or, magnesia) occurs in nature as a solid white mineral. It is relatively rare in North America, which explains why it is generally more expensive than gypsum in the U.S. But magnesium is the third most common element in the oceans, and research is underway to convert the magnesium in seawater into MgO usable for construction purposes. That innovation would make it much more affordable while greatly enhancing sustainability in construction.

3. High-Efficiency Light Ballasts

Lighting is one of the major energy consumers in most buildings. So, it’s in everyone’s interests to reduce that consumption without compromising the quality of light. In keeping with today’s emphasis on energy efficiency, fluorescent light ballasts are now available that consume less energy and therefore reduce costs in the long term. The Federal Emergency Management Agency (FEMA) provides guidelines for builders seeking the most energy efficient light ballasts to benefit their users over the years.

4. Transparent Wood

As strange as it sounds, transparent wood is a real product that has immense potential for the building trades. It’s produced by applying hydrogen peroxide to a wood surface and then exposing it to ultraviolet rays. This removes parts of the lignin molecules that make wood opaque. The pores in the remaining tissue are filled with epoxy. The resulting product retains the strength and insulating qualities of wood, while allowing 90 percent of light to pass through. It’s lighter and stronger than glass and can be used for windows, skylights, and potentially, even roofs and walls, to create see-through houses. The possibilities are staggering.

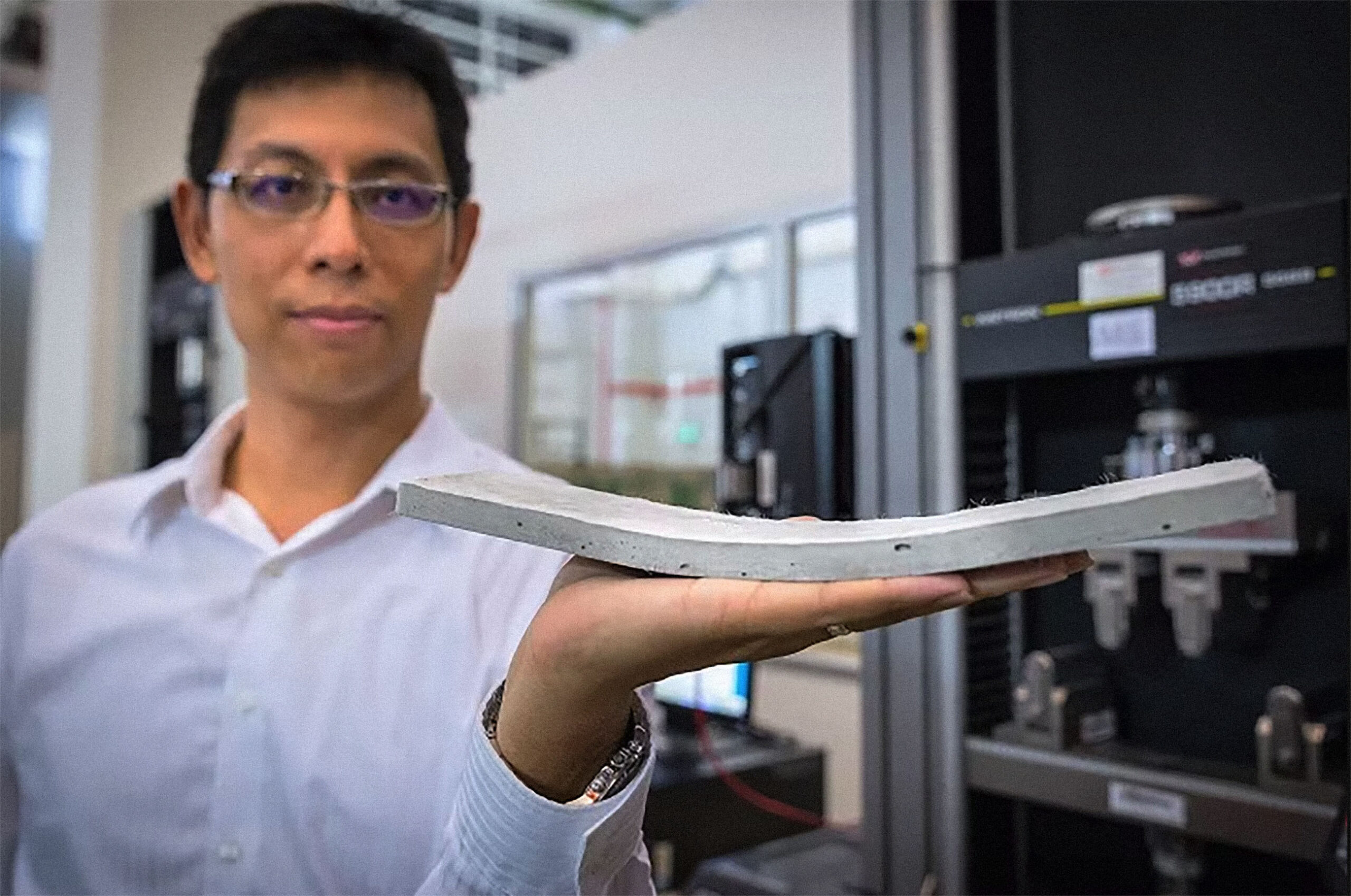

5. Flexible Concrete

Everyone is familiar with the cracks that can develop in conventional concrete, from sidewalks to high-rise buildings. This is due to an innate flaw in this otherwise reliable material—its low tensile strength. That leads to limited lifespan and high maintenance costs, especially for concrete roads and highways.

Professor Victor Li of the University of Michigan developed a method of producing concrete that allows it to flex, increasing its tensile strength and compressive strength significantly. Flexible concrete is 20 to 40 percent lighter than conventional concrete. It also possesses a self-healing property, which allows cracks to be filled in through interaction with moisture. The strain capacity of this innovative product is an amazing 300 times greater than that of conventional concrete.

Flexible concrete is produced by adding fibers to increase the tensile strength of the material. These may be made of silica, asbestos, glass or steel. Superplasticizers are also introduced into the mix–typically, chemicals such as naphthalene, melamine formaldehyde, lignin, sulphonate, polycarboxylate ether, or lignosulfonates.

To date, flexible concrete has been widely used for construction of roads and bridges, which must withstand great tensile stress. It is also ideal for constructing earthquake-resistant buildings and for concrete canvas applications.