All About Metal Roof Installation

In designing any commercial or industrial building, one of the most important decisions is the selection of roof materials. Builders have a number of choices, each having with their own benefits and drawbacks:

Asphalt is a popular and economical choice for many commercial buildings. It is fire-resistant and can last up to 30 years. But it is subject to punctures and other damage, and it can deteriorate over time.

Thermoplastic polyolefin (TPO) has many of the benefits of asphalt, with the added advantage of being light-reflective, which can reduce cooling costs and carbon emissions. But like asphalt, it is subject to puncturing. And as a single-ply membrane, it can encounter problems with laps and flashing.

Ethylene Propylene Diene Terpolymer (EPDM) is a synthetic rubber material that resists thermal shock and hail damage. Being flexible, it can withstand structural movement. It also withstands damage from UV radiation and is recyclable. But EPDM cannot be installed over existing petroleum-based roof material. And it can be damaged through abuse.

This brings us to metal roofing materials, the choice long-preferred for commercial buildings.

The reasons for metal’s popularity are many:

- A metal roof can last more than 50 years.

- It can be repainted or sealed rather than replaced.

- It can withstand winds of more than 140 MPH (the equivalent of an F2 tornado).

- It is completely fireproof.

- It can reduce insurance costs.

- Its strong surface protects against the impact of debris

- It reflects the sun’s radiation, reducing cooling costs and emissions.

- It transfers heat more efficiently than other materials.

- It is completely recyclable.

- It can save up to 25 percent on energy costs.

- Metal roofs are typically installed as large interlocking panels that resist uplift, reducing the risk of water intrusion.

For these reasons, though metal roofs typically cost somewhat more than the other options, they remain a popular choice among commercial builders.

Stopping Rust Before It Starts

Metal does oxidize, producing what we know as rust. To arrest this process, metal roof material receives a rust-resistant coating, which can be reapplied every five years or so. Often, this is the only regular maintenance that a metal roof requires.

There are two commonly used types of rust-resistant steel:

Galvanized Steel is coated with a protective zinc oxide alloy and finished with a resin coating that produces a smooth, shiny finish, resistant to scuffing and scratching.

Galvalume Steel receives a coating of aluminum, zinc, and silicone that resists corrosion and rust. It is ideal for high-temperature, high-precipitation, and marine environments.

Installing a Metal Roof the Right Way

The roof of any structure is among its most important components; after all, it is what protects everything underneath it, whether it be machinery, office equipment, supplies, or products for sale. So, along with top-grade materials, quality workmanship is all-important.

With all roofs, the areas of most concern are the junctions, transitions, seams, and any places where flashing is required. Inadequate installation can cause leaks, allowing moisture into the structure below. The places where fasteners are applied on a roof are also vulnerable. A large percentage of roof leaks are caused by improperly installed fasteners.

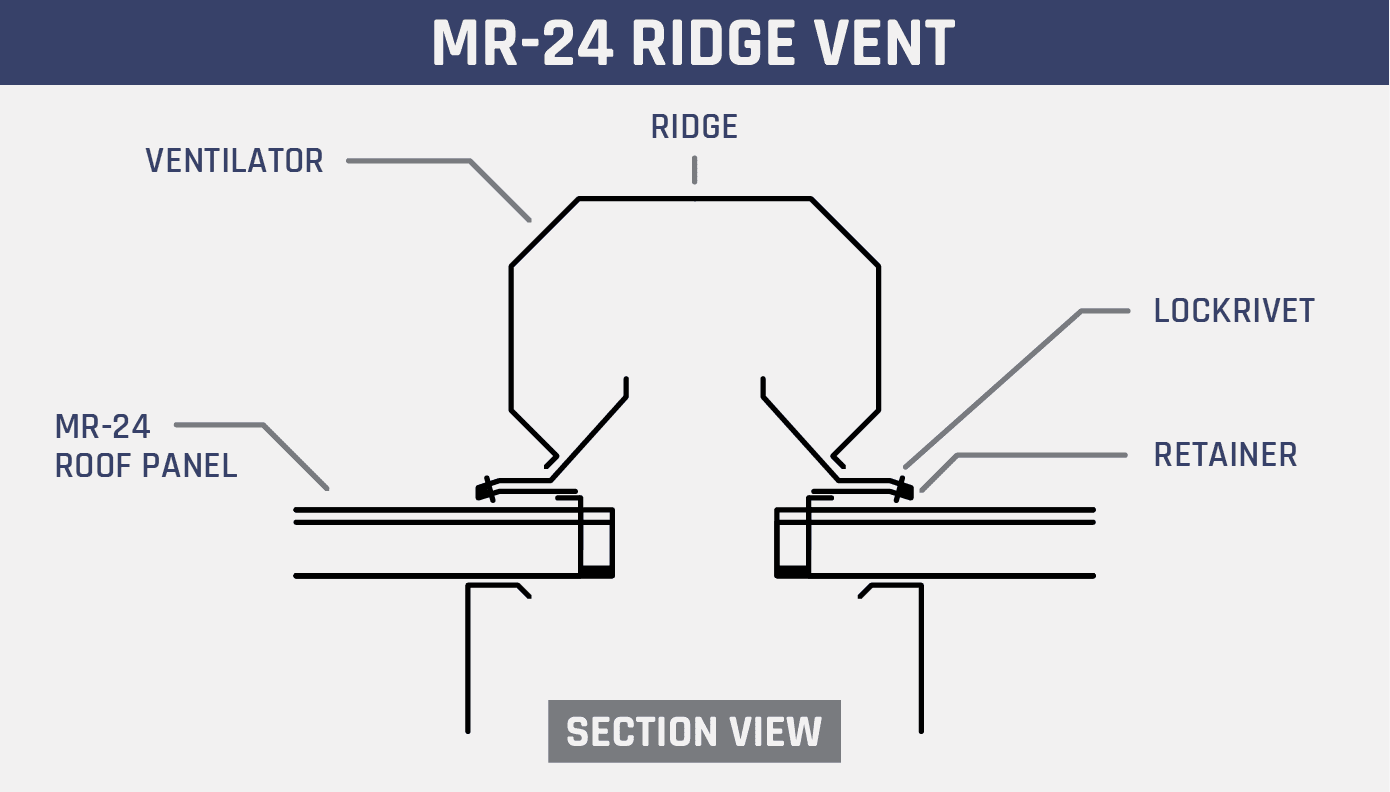

Standing seam metal roofs minimize this risk by employing interlocking panels with concealed fasteners. The panels have raised vertical legs or ribs at each end, which contain the fasteners above the level of the roof. A superlative example is the MR-24 Standing Seam Metal Roof from Butler Manufacturing. Its gable trim system features a top trim piece fully seamed into the roof panel with a bottom piece that attaches to the wall. These two pieces come together in a slip joint that allows the whole assembly to travel with the roof panels as they expand and contract.

Installing a Metal Roof Over the Existing Roof

Most non-metal roofs can be retrofitted with metal without the necessity of removing the existing material. This avoids the lost time, cost, risk, and inconvenience of a remove-and-replace project. With flat or low-slope roofs, a common practice is to build a substructure to enhance the slope of the roof before applying the metal panels.

What About Warranties on a Metal Roof Installation?

A properly installed metal roof can last as long as 70 years with minimal maintenance. So, most reputable companies offer generous warranties. But there are important things to be aware of. There are basically two types of warranties on a metal roof installation:

Workmanship Warranties—Issued by the Installer. These typically cover any failures that can be proved to be the result of poor installation.

Materials Warranties–Issued by the Manufacturer. These may cover periods as long as 50 years or more. But beware: Some warranty agreements prorate their coverage based on the remaining useful life of the roof. It’s important to read the fine print!

It’s also important to have ready access to support after the installation. A good roofing partner will be there for you long after the job is done.