How a PEMB Can Be Customized

Today’s PEMB is much more than just a big box!

Pre-engineered metal buildings (PEMB) are prized for their versatility, low cost, and ease of construction. By opting for a PEMB over traditional construction, a builder can cut construction time by as much as a third. A PEMB can be erected in days, rather than weeks or months. The use of lighter materials typically means much lower costs. And large clear spans allow for extremely wide designs without the need for additional internal framing. This makes PEMBs suitable for a variety of uses, including warehouses, distribution centers, workshops, breweries, horse barns, airplane hangars, sports facilities, government buildings, and even churches.

Some people think of PEMBs as large, featureless boxes. But nothing could be farther from the truth. While they are ideal for uses that require a large open space, PEMBs can also be customized to fit any user’s need or desire.

Here are some of the features of a PEMB that lend themselves to customized treatments:

Size

In designing any building, the space requirements are a primary consideration. And the ability to enclose large spaces with a minimum of structural elements is one of the strengths of PEMB construction. Among the crucial dimensions to consider are the width (especially for clear span construction), the length (which will partially determine the number of bays, or frame units), and the eave height (measured from the top of the foundation to where the sidewalls meet the roof) The slope of the roof will determine the height of the peak (the highest point of the roof).

A small retail store might only require a structure of 2,000 square feet or so. But for warehouses, sports facilities or heavy equipment storage buildings, huge spaces are often required. The simple structure of PEMBs allows them to be scaled to almost any dimension. A typical PEMB might have an eave height of 40 feet, but some can reach heights of 100 feet. When mezzanines or second floors are added, the height requirements increase.

The Boeing production facility in Everett, Washington illustrates the near-infinite size possibilities of metal buildings: It is the world’s largest metal building as well as the largest manufacturing building, occupying an astonishing 472 million cubic feet over 98.3 acres. So, size is clearly not an obstacle for PEMB design.

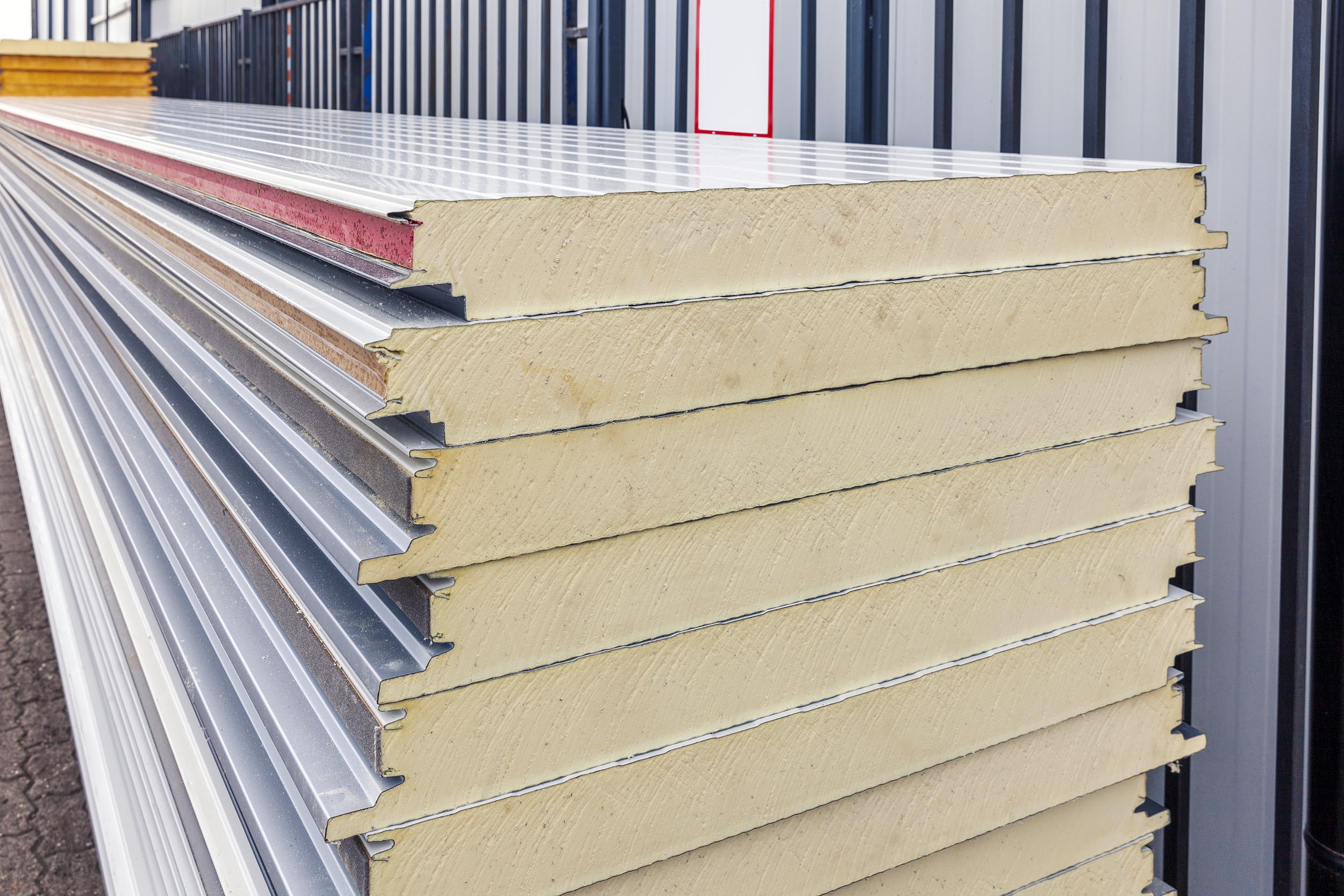

Cladding

PEMBs are typically clad with high-strength, corrosion resistant, insulated steel panels. But there are many colors and channel designs available. The choice of appropriate color and design can yield a distinctive look to any PEMB, making it appropriate for the intended purpose and brand image. PEMBs can also be finished with wood, masonry, or glass panels.

Doors, Windows & Openings

Openings in a metal building, whether they include doors or not, are usually incorporated as part of the framing structure. So, their placement is an essential consideration in the early design phase.

How many framed openings will a building require? How wide and how high? With a PEMB, the options are virtually limitless. A helicopter hangar may require large openings at the front and back, while a building used strictly for office space may only require a few standard-sized walk-in doors. A PEMB can accommodate both—and everything in between. Large openings can be enclosed with sliding overhead doors, sectional doors, or cylinder drum style doors.

Windows in a PEMB can be incorporated in the initial framing design or retrofitted later in the field. The number and placement of windows may be dictated by the need for sunlight and energy efficiency, or simply for aesthetic reasons. Some PEMBs have incorporated glass panels for entire walls.

Skylights can serve a function similar to windows, providing welcome light in otherwise darkened environments without compromising privacy. These features also contribute to energy efficiency by reducing the need for electric light.

Interior Layout

The large clear spans that are possible with a PEMB allow for nearly unlimited choices in interior layout. Rooms or sections of almost any number, size or shape can be incorporated without the need for additional framing—since the main frame supports the entire structure. This makes PEMBs equally suitable for a large sports gym, an office with multiple cubicles, or any combination of uses.

Climate Control

A common misconception is that metal buildings are not conducive to effective climate control. In fact, today’s PEMBs incorporate all the effective climate control mechanisms that conventional buildings use. Here are some of the factors that can optimize climate control in a PEMB—whether it exists in a hot or cold climate:

Insulation

Effective insulation is the first line of defense in controlling against extreme heat or cold. PEMBs today are typically clad with insulated metal panels, which do the job quite effectively. Special attention should be paid to the roof insulation, which can reduce heat loss during cold months and repel solar radiation during the hot days of summer.

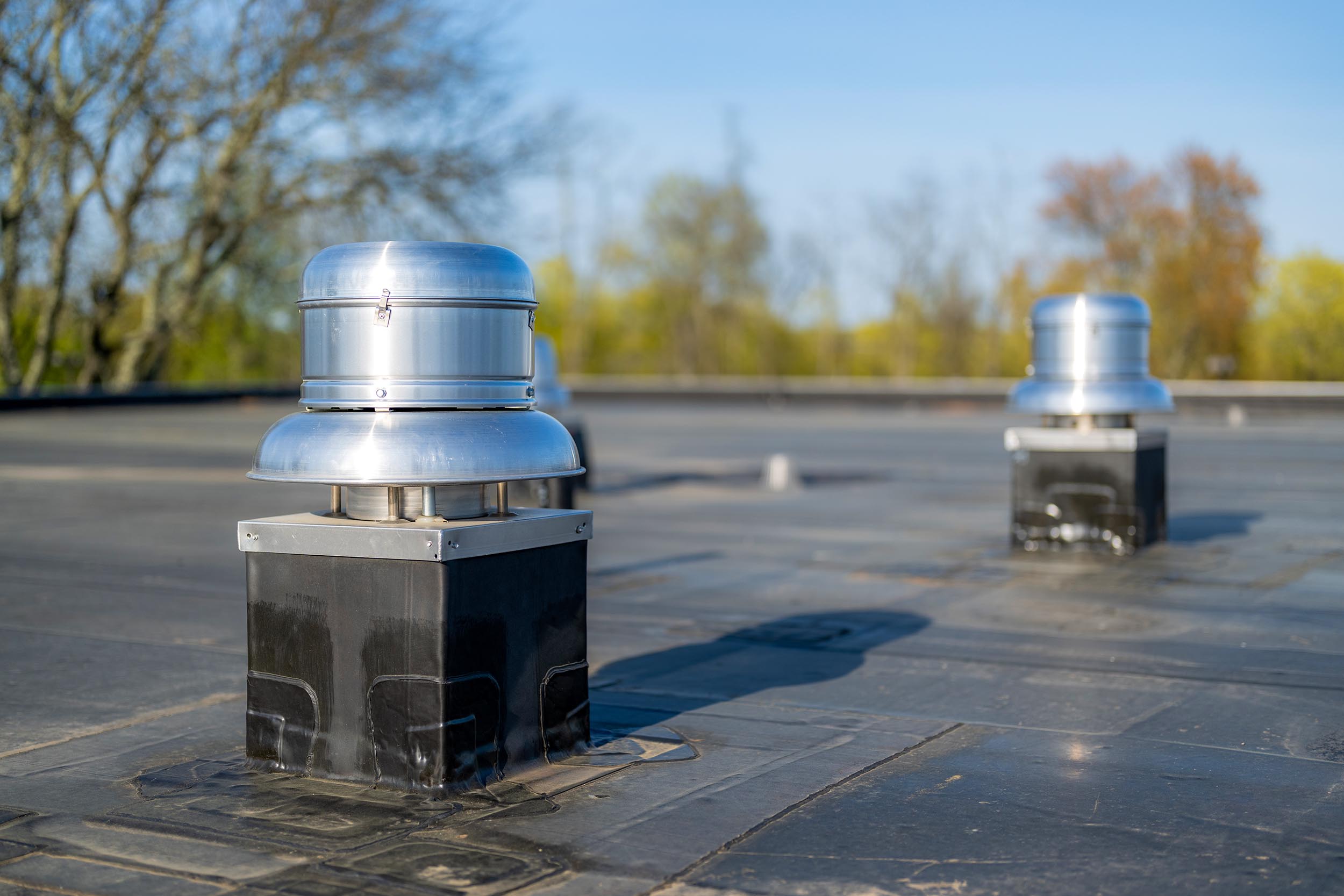

HVAC

An efficient HVAC system is just as essential in a PEMB as in any other structure. Gravity vents can provide extra heat reduction by drawing hot air up into a roof fan and out into the atmosphere. Along with removing heat, this mechanism promotes air circulation in the building—all without imposing any extra load on the HVAC system.

Windows

In cold climates, strategically placed windows can help capture the solar rays and warm a building’s interior. Conversely, in hot climates it can be best to avoid south-facing windows, which are particularly exposed to the sun’s radiation. (The reverse is true for buildings in the Southern Hemisphere, where north-facing windows receive the most solar radiation.)

Exterior structures

Placing awnings, lean-tos, or overhangs on doors and windows can provide shade and reduce interior heat

Landscaping

Greenery on a building’s grounds does more than provide a pleasing aesthetic. Trees, placed strategically, can provide welcome shade and protect the structure from the sun’s rays. And plants of all types can reduce the temperature around a building by releasing moisture into the atmosphere, cooling the air as it evaporates.

Foundation Options

As with any building, the foundation of a PEMB is one its most important components. And it is one of the few elements that must be constructed onsite. Like other buildings, most PEMB foundations are concrete slabs. But the type, depth, and strength of the foundation must be determined based on a number of factors:

-

Local building codes

-

Soil composition

-

Size of structure

-

Building loads

There are several load categories that a building and its foundation must be able to withstand. Among them:

Wind Load

Metal buildings are lightweight compared to other structures. This makes them more vulnerable to wind. So, their foundations must be heavier to resist the lateral and uplifting forces of wind.

Seismic load

This applies especially in areas prone to earthquakes and other seismic activity.

Snow Load

Snow, when it accumulates on a rooftop, can exert a great force on a structure. In areas prone to heavy snowfall, the foundation structure must be built with that in mind.

Dead Load

This refers to the weight of the building itself, which exerts downward pressure on the foundation.

Live Load

This is the weight of the building with all equipment, people, and objects included. This becomes especially important when a structure is meant to house heavy machinery or equipment.

With all these considerations in mind, it’s best to use the services of a structural engineer in designing the foundation of a PEMB.

Structural Additions

While the basic structure of a PEMB is simple—one of its most attractive features—that doesn’t mean the building itself must be simple, uniform, or boring. Many PEMBs incorporate complex designs to accommodate the varied needs of the enterprises they house. And for businesses that anticipate growth or diversification, it’s smart to allow for the possibility of additions in the early design phase.

Interior Finishes

Choices for the interior of a PEMB are important not just for their structural qualities, but because that’s where people will be spending their time. A pleasant environment makes for happier workers, guests, and customers. Fortunately, there are plenty of esthetically pleasing interior finishes available for PEMBs that are also structurally appropriate.

Walls

To begin, the basic wall materials must be chosen. Choices include:

-

Metal

Some PEMB owners opt to continue the metal theme with interior partitions made of metal. These have the advantage of being strong, fireproof, and easy to clean. Like other surfaces, they can be painted in a variety of colors.

-

Drywall

This common choice offers a smooth, uniform surface that is also fireproof. But it is not usually recommended for the outer walls of a PEMB, since it can be damaged with normal movements of the structure.

-

Plywood

This is a trusted standby for interior paneling, and for good reason. It’s strong, can hold mounted shelving or tools, and is easy to repair.

-

Oriented Strand Board (OSB)

This composite offers many of the benefits of plywood while being cheaper. But it is not generally as strong as plywood and cannot be painted.

Once a wall material is chosen, there are nearly limitless choices of colors and textures available to add esthetic appeal to a building’s interior.

Flooring

Like wall treatments, there are many choices available for flooring. Some PEMBs take a utilitarian approach, leaving the bare concrete floors.

Other options include:

-

Stained Concrete

-

Epoxy

-

Waterproof Vinyl

-

Natural Stone

-

Wood

The intended use of the structure must be considered in the choice of flooring, but esthetic appeal should also play a part.

All these features demonstrate how a PEMB can be unique, versatile, functional, and attractive—all at the same time.