Summer Management for PEMBs

As heat waves sweep over North America, attention naturally turns to effective ways to cope with the soaring summer temperatures. Today’s pre-engineered metal buildings (PEMB) are built to function well in all kinds of weather, with features such as state-of-the-art insulation and cool roofing. But there are further steps building owners and managers can take to keep their PEMBs operating efficiently in the summer heat.

PEMB Summer Management Begins in the Construction Phase

Protection against temperature extremes starts with the choice of construction materials. Here are some components of a PEMB that can keep the harsh weather outside rather than inside:

Insulation

Choosing the right insulation is critical for creating and maintaining a pleasant indoor environment. Besides reducing heat loss in winter and heat gain in summer, good insulation can absorb sound and reduce moisture condensation. The effectiveness of insulation in resisting heat transfer is indicated in its “R-value.” The higher the R-value, the more effective it is.

Let’s look at the types of insulation typically used in a PEMB.

Fiberglass is still the insulation material of choice for many PEMBs. It comes in single- and double-layer sheets, in thicknesses ranging from 2.5 inches to 10 inches. Its R-value can vary from 8 for a 2.5 inch thickness to more than 43 for the thickest double-layer rolls. Fiberglass often offers the best R-value for the money, which is why it remains popular among builders. Humidity is a major concern for building owners and operators in some regions. Fiberglass insulation with vapor retarders reduces the amount of water vapor that enters the building through the roof and walls.

Spray foam insulation creates an effective barrier that can retain its structure indefinitely. Unlike some other forms of insulation, it does not sag or compress over time. It is especially useful in small, tight, or hard to reach areas. Once applied, it can expand up to ten times its original volume. While generally more expensive than fiberglass, it can provide a higher R value.

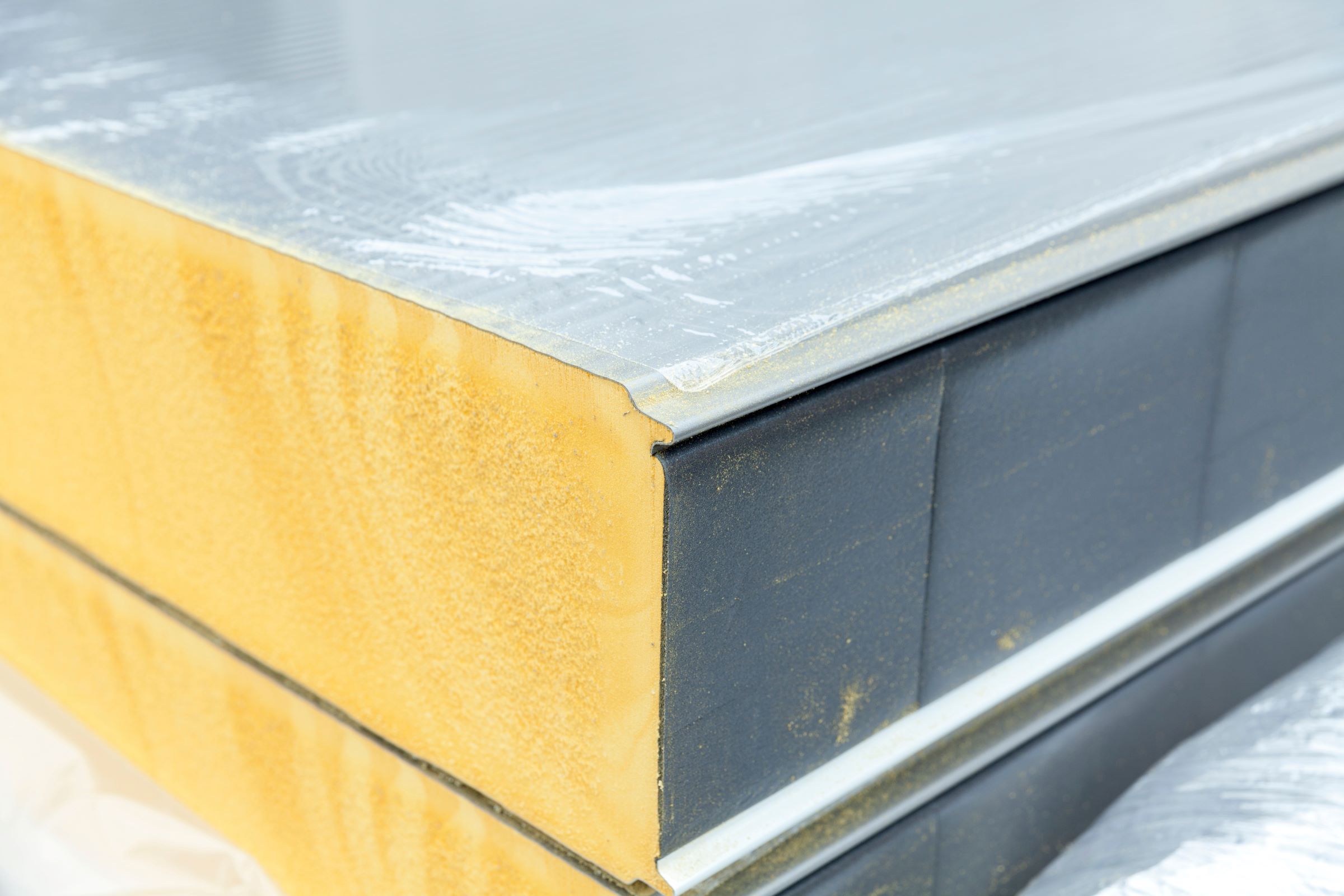

Foam insulated metal panels provide effective insulating properties with convenience in installation.

Roofing

Metal remains among the most popular choices for roofing on a PEMB, and with good reason. Properly installed and maintained, a metal roof can last more than 50 years. It reflects solar radiation, reducing the need for cooling and the accompanying costs. The strength of metal is one of its most attractive attributes; it protects the structure from damage due to debris and can withstand hurricane-force winds. Although all metal is subject to oxidation, today’s galvanized steel and galvalume steel resist corrosion as well as scuffing and scratching. Metal doesn’t decompose like some materials. And of course, metal is fireproof.

Asphalt roofing is another option for metal buildings, as well as residential construction. Generally considered more economical than metal, an asphalt roof can last up to 30 years. Asphalt can deteriorate over time and is vulnerable to punctures and other damage.

Other roofing materials include Thermoplastic polyolefin (TPO), and Ethylene Propylene Diene Terpolymer (EPDM), both of which reflect light but are subject to damage from punctures and abrasion.

Cool roofs are designed to reflect as much solar radiation as possible, using light colored coatings and other pigments that selectively reflect near-infrared radiation frequencies. This approach can reduce the temperature of a roof by as much as 50 degrees Fahrenheit. That, in turn, reduces the load on the interior HVAC system, saving energy and money.

Ventilation

Vigorous air flow is important in maintaining a cool, healthy environment for any structure. So, strategically placed vents and fans are vital components of today’s PEMBs. When air circulates freely, it can lower temperatures, reduce moisture and condensation, and improve air quality. That makes life more comfortable for the people inside while prolonging the building’s useful life.

Summer Maintenance for PEMBs

Even well-constructed buildings need wise management and periodic maintenance to stay efficient. That need often becomes apparent when summer temperatures hit their peak. Here are some ways to get the most out of a PEMB during the summer months.

- A building’s most important defense against extreme heat is its HVAC system, so it makes sense to take good care of it. That starts with changing the air filters monthly and cleaning the air ducts annually. Make sure there are no obstructions blocking the skirting vents and air return vents.

- Mold thrives in warm, moist environments, so it’s wise to run the AC on summer days even when the building is unoccupied. And to avoid overworking the system, thermostat settings should always be set at moderate levels.

- Beyond the basic thermostat, PEMBs can now use building automation systems (BAS) to control HVAC, lighting, and water usage, as well as virtually every other aspect of the structure’s day-to-day operation. A well-functioning BAS can reduce energy costs by as much as 20 to 40 cents per square foot.

This technology is part of smart building design, which uses sensors to exert precise control over the various elements of a building’s environment. For instance, the sensors can detect when a building or room is unoccupied and reduce lighting and air conditioning in that space to save energy.

- Maintaining the roof on a PEMB is a must—and also easy to forget. The good news about metal roofs is that they can last half a century or more. They do have a rust-resistant coating, however, that should be reapplied every five years or so. Beyond that, the roof should be inspected periodically to make sure there’s no damage from the elements.

Roof inspections are especially important for roofs made of asphalt, TPO, or EPDM, which can be damaged by debris, falling branches, or simple corrosion.

Making it Through the Long, Hot Summer

With a little timely maintenance and wise management, a PEMB can get through the summer heat without sacrificing longevity or comfort for those inside.